Page 23 - Tiling Guide Uniclass Index

P. 23

SPECIAL INSTALLATION CONSIDERATIONS

Tiling with Underfloor Heating

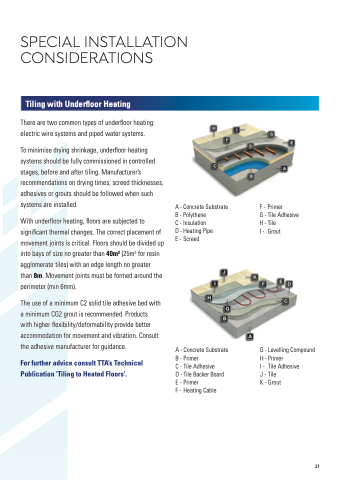

There are two common types of underfloor heating: electric wire systems and piped water systems.

To minimise drying shrinkage, underfloor heating systems should be fully commissioned in controlled stages, before and after tiling. Manufacturer’s recommendations on drying times, screed thicknesses, adhesives or grouts should be followed when such systems are installed.

With underfloor heating, floors are subjected to significant thermal changes. The correct placement of movement joints is critical. Floors should be divided up into bays of size no greater than 40m2 (25m2 for resin agglomerate tiles) with an edge length no greater than 8m. Movement joints must be formed around the perimeter (min 6mm).

The use of a minimum C2 solid tile adhesive bed with a minimum CG2 grout is recommended. Products with higher flexibility/deformability provide better accommodation for movement and vibration. Consult the adhesive manufacturer for guidance.

For further advice consult TTA’s Technical Publication ‘Tiling to Heated Floors’.

A - Concrete Substrate B - Polythene

C - Insulation

D - Heating Pipe

E - Screed

F - Primer

G - Tile Adhesive H - Tile

I - Grout

A - Concrete Substrate B - Primer

C - Tile Adhesive

D - Tile Backer Board E - Primer

F - Heating Cable

G - Levelling Compound H - Primer

I - Tile Adhesive

J - Tile

K - Grout

21